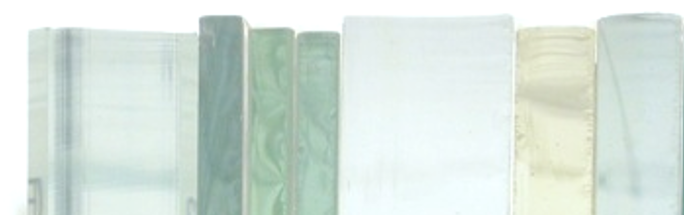

Clear glass is extremely common and is popular in a variety of architectural design applications. However, when specifying glass to achieve a truly transparent aesthetic, design professionals know that clear glass isn’t completely clear—it has a distinct green hue when viewed under light.

A double-glazed insulating glass unit (IGU) consist of two glass lites, separated by an airspace.

Often, design professionals specify a double-glazed IGU with low-iron glass as the exterior lite—typically to achieve greater transparency and color fidelity—and then use clear glass as the interior lite. This compromises the design intent of maximizing daylight and color fidelity, as the green hue that is inherent in clear glass will dilute the clarity of the low-iron glass on the exterior lite.

For a truly transparent look, use low-iron glass for both lites in a double-glazed IGU.

Scratch-Resistance and Strength

Low-iron glass has the same surface hardness and resistance to abrasion and scratching as standard clear glass, which means its color fidelity and clarity is as protected from scratches and scuffs as clear alternatives, with less green distortion. Additionally, while surface hardness is not the same as tensile strength, both low-iron and clear glasses also offer the same tensile performance.

Here's how it works: low-iron and clear glasses are produced using the same float process and equipment but require different levels of purity in raw materials. This results in the remarkable clarity and brilliance for which low-iron glass is known.